Producing high-quality products and improving work efficiency.

Bubble-prevention Agent CML is a product containing calcium oxide as a major ingredient and it has been developed with our own technique and know-how. By chemical reaction, it eliminates moisture that negatively affects the quality of rubber, resin, vinyl chloride sol and sealant and it solves physical problems caused by moisture that materials contain.

Superfine particles of calcium oxide that can absorb moisture in the target efficiently are used for CML. This calcium oxide is highly active powder with high dispersibility that is produced with our own superior technology. We treat it with appropriate dispersion medium according to application in order to correspond to each application. So, with proper compound, it can eliminate moisture in the target completely and make the quality stable.

Currently、we are developing Bell-CML for olefin resin. Unnecessary drying process can be omitted before molding by adding bubble-prevention agent and Bell-CML in which olefin resin is made into master pellets.

- Usage Example

- Various types of rubber products, various plastic products, adhesives and sealants

Products Lineup

Bubble-Prevention Agent CML

CML#21・#22P

It is a bubble-prevention agent for rubbers (paste・ wet powder) using specially compounded oil as dispersion medium.

CML#31

It is highly dispersive powder whose surface is treated with fatty acid and is used especially for vulcanizing UHF of EPDM.

It can be used for vinyl chloride resin and urethane products as well.

CML#35

Dispersion medium is not used so it can be used for every kind of rubber and resin.

| Cao(%) | Dispersion Medium | Appearance | Main Use | Packing Unit | |

|---|---|---|---|---|---|

| CML#21 | 76 | Special Oil Solution | Wet Powder | Rubber | 20kg(5kgx4) |

| CML#22P | 88 | Special Oil Solution | Wet Powder | Rubber | 18kg(6kgx3) |

| CML#31 | 96.5 | Fatty acids | Powder | Resin, Rubber, Sealant | 20kg(20kgx1) |

| CML#35 | 100 | – | Powder | Resin, Rubber, Sealant | 15kg(15kgx1) |

Weight above is a specification for standard goods.

We can respond to the weight except for above and to small portion, so please consult with us.

CML has property to easily absorb moisture because its main component is calcium oxide.

After opening, it easily reacts with moisture in the air and deteriorates rapidly and may lose its original property, so please use as soon as possible after opening.

※Data above are representative values and they do not guarantee the quality.

Bubble-Prevention Agent master pellets

Bell-CML

We developed Bell-CML for olefin resin. Unnecessary drying process can be omitted before molding by adding bubble-prevention agent and Bell-CML in which olefin resin is made into master pellets.

Bell-CML P

PP-based masterbatch for olefin resin, pellet-type.

Bell-CML EO,EM

PE-based masterbatch for olefin resin, pellet-type.

Bell-CML EP810,EP810L

In addition to existing Bell-CML, which is recommended for EPDM base compound, we have prepared EPDM-based new grades. The absorption capacity compares well with the conventional grade and compared with conventional grade, there are merits as follows.

- Improvement of dispersivity.

- Extention of product life.

- Improvement of handling ability.(It is masterbatch so it is not dispersed and does not pollute the factory environment.)

The physicality after compound is same as conventional products.

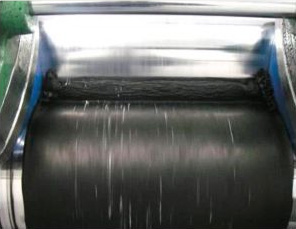

Comparison of dispersivity.

EP810

Right after injection

One minute later

CaO powder

Right after injection

One minute later

※Comparison in the roll kneading

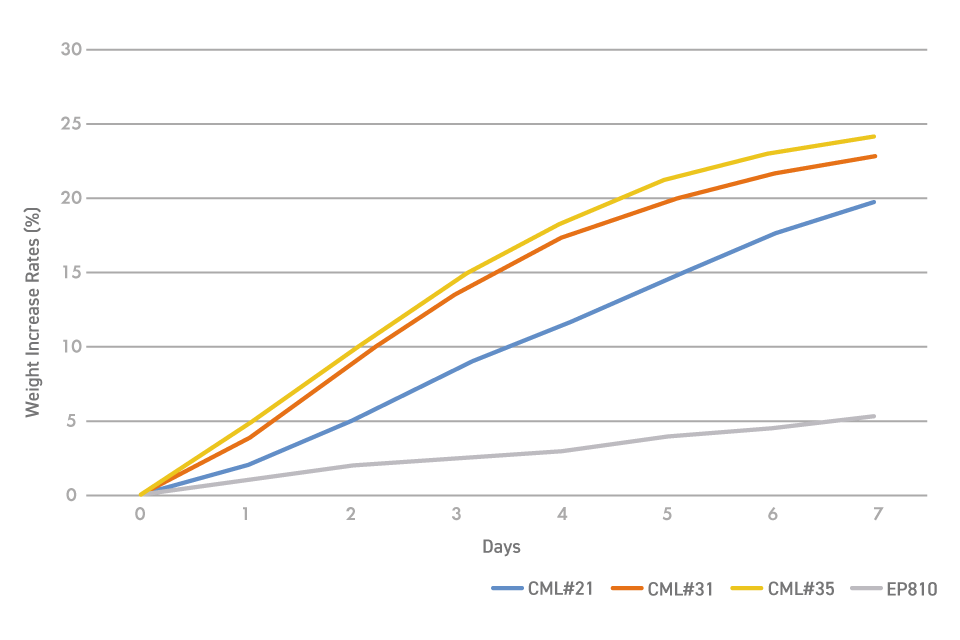

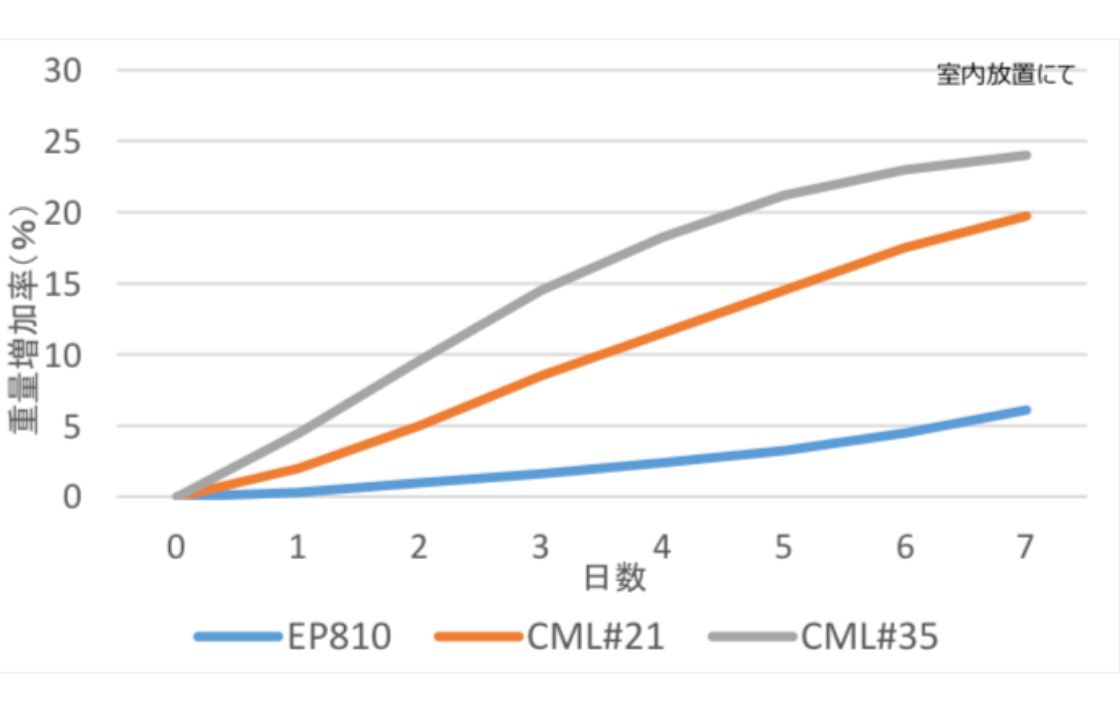

Comparison of product life

| Cao(%) | Base Polymer | Appearance | Main Use | Packing Uni | |

|---|---|---|---|---|---|

| Bell-CML EO | 50 | LDPE | Pellet | Sheet | 12kg(4kgx3) |

| Bell-CML EM | 65 | LLDPE | Pellet | Sheet | 12kg(4kgx3) |

| Bell-CML P | 83 | PP | Pellet | Sheet | 15kg(5kgx3) |

| Bell-CML EP810 | 80 | EPDM | Pellet | Rubber | 15kg(5kgx3) |

※Data above are representative values and they do not guarantee the quality.

Effect of compound to CML molding products.

With CML added.

CML absorbs moisture in the material and does not foam, so the appearance looks stable.

With no CML added.

Moisture in the material foams and appears in the molding products so the measurement is not stable.

The reaction rate of CML with water.